1. Sorts of Bond and Properties

1) Metal Bond(symbol M)

The metal bond is manufactured by mixing the metal power such as iron, bronze, tungsten, and cobalt, etc. with super-abrasive

(Diamond, CBN) and sintering it.

* Properties

- High Grinding Ratio

- Excellent in Form-maintaining ability

- Excellent in Bond’s Toughness, Abrasivity-Resistance, and thermal resistance

- It requires high grinding power.

- Easy occurrence of clogging and brittleness because of its excellent coherent power of abrasive grain

2) Resin Bond (symbol B)

It is manufactured by mixing synthetic resin (phenol series, polyimide series) and filler with abrasive grain.

* Properties

- Excellent in Free-Cutting Ability

- It can create excellent processing surface and high grinding performance due to plenty of elasticity.

- Wide Applications

- It’s available to use it even by low grinding power.

3) Vitrified Bond (symbol V)

It’s a fragile bond manufacture by using vitric binding agents, and it is more excellent in coherence than resin bond;

in addition, it can regulate solidity and chip-discharging performance by giving change to porosity.

* Properties

- It has a very excellent abrasivity-resistance

- It has an excellent form-maintaining ability

- It’s easy for truing and dressing.

- It has a wide range of surface roughness.

- It creates less clogging and heat release.

2. Comparison of Performance Properties by Bond

Properties of Grinding Wheel by Bond | ||||

Grinding Property | Resin | Metal | Vitreous | Electroplating |

| Life Span of Grinding Wheel | Medium | High | High | Low |

Material Removal Rate | High /Medium | Medium | High /Medium | High |

Form Retaining Power | Medium | High | High | High |

Required Power | Medium | Medium / High | Low | Low / Medium |

Difficulty in Truing/ Dressing | Medium | High | Low | Usual Needlessness |

Surface Roughness | Good | Good / Average | Best | Diverse |

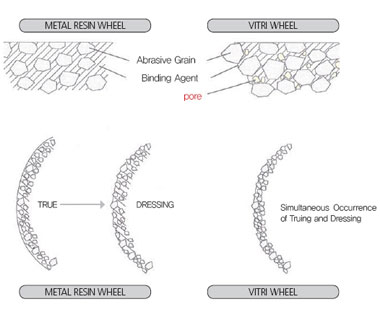

3. Wheel Structure according to sorts of Bond

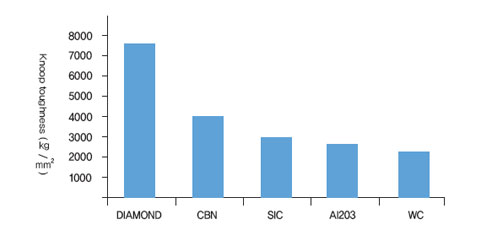

4. Comparison of Abrading Agent Toughness

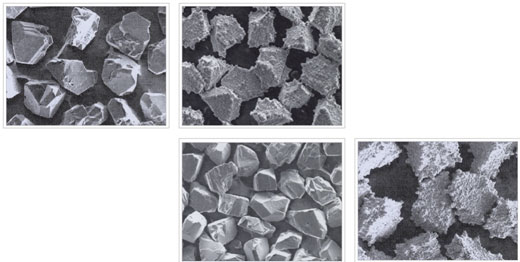

5. Form of Abrasive Grain(Diamond, CBN)

6. Grain-size Chart of Abrasive Grain

GRANULARITY | FEPA | APPLICATION | MESH | MICRON(㎛) | APPLICATION |

#20/30 | D/B 852 |

| #600 | 30~40 | Lapping |

#30/40 | D/B 602 |

| #700 | 22~36 |

|

#40/50 | D/B 427 |

| #800 | 20~30 |

|

#60/80 | D/B 301 |

| #1000 | 15~25 |

|

#80/100 | D/B 252 |

| #1200 | 10~20 | Polishing |

#100/120 | D/B 181 | #1800 | 6~12 |

| |

#120/140 | D/B 151 | grindigri | #2200 | 5~10 |

|

#140/170 | D/B 126 |

| #3000 | 4~8 |

|

#170/200 | D/B 107 | #5000 | 3~6 |

| |

#200/230 | D/B 91 |

| #8000 | 2~4 |

|

#230/270 | D/B 76 |

| #12000 | 1~3 |

|

#270/325 | D/B 64 |

| #14000 | 0~2 |

|

#325/400 | D/B 54 |

| #28000 | 0~1 |

|

#400/500 | D/B 46 |

| #60000 | 0~1/2 |

|

7. Optimum Wheel Peripheral Speed= External Diameter of Wheel X 3.14X Rev Count of Pivot(R.P.M)= m/min

Binding Agent | Using Condition | WHEEL | CBN WHEEL |

RESIN WHEEL | Use of Wet Process | 900 ~ 1800 | 1000 ~ 2000 |

Use of Dry Process | 700 ~ 1200 | 800 ~ 1500 | |

METAL WHEEL | Use of Wet Process | 800 ~ 2000 | 800 ~ 1500 |

| Use of Dry Process | 500 ~ 800 | - |

VITRI WHEEL | Use of Wet Process | Less than1500 | More than1800 |

Surface Roughness | Good | Good / Average | Best |

8. Optimum Quantity of Depth of Cut

MESH | WHEEL | CBN WHEEL |

80 ~ 120 | 0.025 | 0.02 ~ 0.05 |

140 ~ 200 | 0.0125 | 0.01 ~ 0.02 |

More than 230 | 0.006 ~ 0.01 | Less than 0.01 |

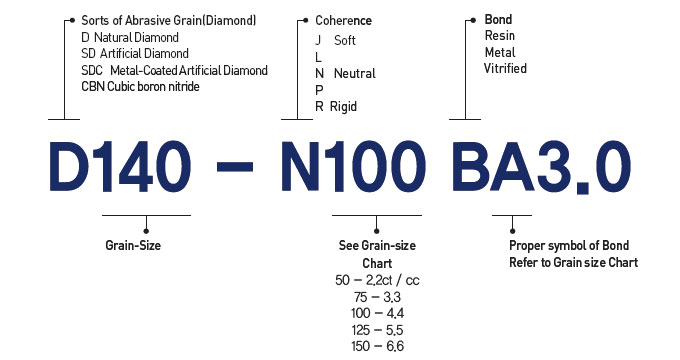

9. Marking Method of Diamond & CBN Wheel

10. Processing Surface Roughness

Maximum Height | Centerline Mean | Square Mean Cubic Root | Ten-point average |

| 0.1 | 0.02 | 0.02 | 0.1 |

| 0.2 | 0.03 | 0.04 | 0.2 |

0.3 | 0.06 | 0.06 | 0.3 |

0.4 | 0.07 | 0.08 | 0.4 |

0.5 | 0.09 | 0.1 | 0.5 |

0.6 | 0.1 | 0.11 | 0.5 |

0.7 | 0.12 | 0.13 | 0.6 |

0.8 | 0.14 | 0.15 | 0.7 |

0.9 | 0.15 | 0.17 | 0.8 |

1 | 0.17 | 0.19 | 0.9 |

1.2 | 0.2 | 0.23 | 1.1 |

1.4 | 0.24 | 0.27 | 1.3 |

1.6 | 0.27 | 0.3 | 1.4 |

1.8 | 0.31 | 0.34 | 1.6 |

2 | 0.34 | 0.38 | 1.8 |

2.4 | 0.41 | 0.46 | 2.2 |

2.8 | 0.48 | 0.53 | 2.5 |

3.2 | 0.54 | 0.61 | 2.9 |

3.6 | 0.61 | 0.68 | 3.2 |

4 | 0.68 | 0.76 | 3.6 |

4.5 | 0.77 | 0.86 | 4.1 |

5 | 0.86 | 0.96 | 4.5 |

5.5 | 0.94 | 1.05 | 5 |

6 | 1.02 | 1.14 | 5.4 |

| 7 | 1.19 | 1.33 | 6.3 |

8 | 1.36 | 1.52 | 7.2 |

9 | 1.53 | 1.71 | 8.1 |

10 | 1.7 | 1.9 | 9.0 |